December 23, 2025

Happy Holidays and Weld 2026.1 Released

As the end of 2025 approaches, Verbotics would like to wish you an enjoyable festive season. It’s been a big year for us, with a new major software release, the expansion of our partner program, and exhibitions in North America and Europe.

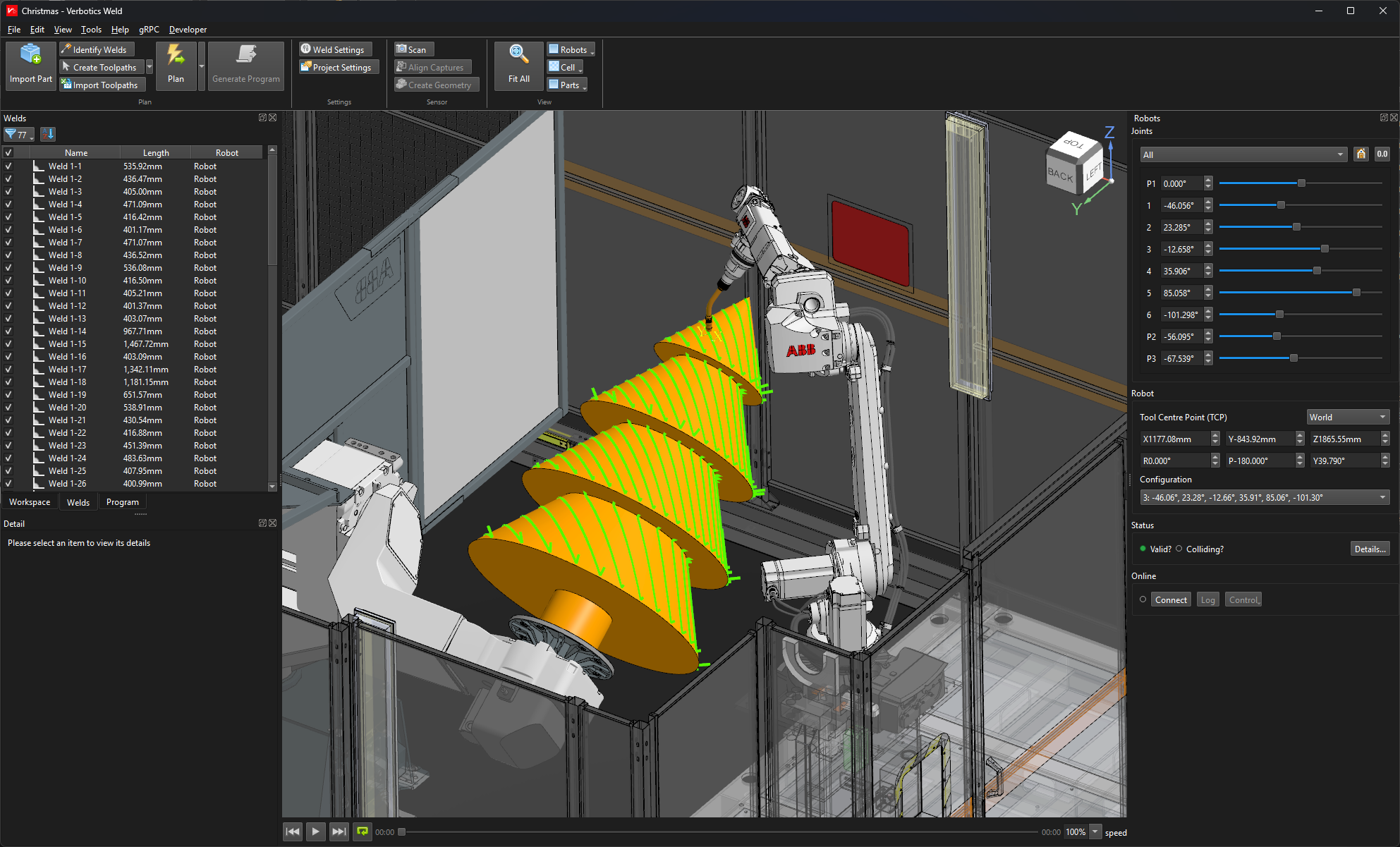

Introducing Verbotics Weld 2026

August 18, 2025

We’ve just published the first release candidate for Verbotics Weld 2026! Weld 2026 is a major update of our robotic weld planning software, and is available to all users of Verbotics Weld.

Read moreVerbotics Announces Partner Integrators

July 7, 2025

Our world-leading programming software is only part of the robotic welding puzzle. We’ve launched our Partner Integrator page so you can find integrators who deploy our software as part of their solutions.

Read moreScan to Weld - The Future of Robot Welding

January 28, 2025

What if your robot could see? What if it could sense and weld the part in front of it, all without programming or CAD models? Unveiling our latest development: Verbotics Scan-to-Weld.

Read moreArronet Case Study: High-Mix Robotic Welding of Aluminium Boats

July 2, 2024

Arronet Technik AB has been designing and manufacturing bespoke boats for over 30 years. Their boats are made entirely in-house with a distinctive unpainted aluminium design style. They produce around 200 boats annually ranging from 18-35 feet, with each boat customised for every order.

Read moreVerbotics Weld 0.12.1 Released

June 16, 2024

We’ve just released Verbotics Weld 0.12.1 with a number of functionality and usability improvements. You can download the latest release here or by checking for updates within Weld (under Help > Check for Updates).

Read moreVerbotics Exhibiting at Australian Manufacturing Week 2024

March 12, 2024

We will be exhibiting at Australian Manufacturing Week (AMW)! Come visit us and see how easy it can be be to program welding robots for high-mix low-volume production, including a live end-to-end demonstration of our welding robot programming software.

Read moreVerbotics Wins the 2023 Technology Application Endeavour Award

December 4, 2023

We’re stoked to announce that our smart robot programming software, Verbotics Weld, has won the Technology Application Award at the 2023 Manufacturer’s Monthly Endeavour Awards!

Read moreOffline Programming Without Touch Ups

November 15, 2023

A question we’re often asked is if programs generated offline by Verbotics Weld need to be touched up. The answer is we try and eliminate or minimise the need for any touch-ups, but there are situations where touch-ups are neccesary.

Read moreVerbotics Weld 0.12

October 26, 2023

We’ve published a new version of Verbotics Weld with support for OTC Daihen and Reis robots, along with a number of other improvements.

Read moreVerbotics Wins at the Australian Technologies Competition

October 3, 2023

We’re over the moon to have won the advanced manufacturing category at the 2023 Australian Technologies Competition! The competition is a national growth and awards program designed to showcase and promote innovative Australian technologies with global growth potential.

Read moreAll About Touch Sensing

August 24, 2023

Path finding (or path calibration) is the ability of a robot to use sensors to account for differences between where it expects a welding path, and where it actually is.

Read moreVerbotics Weld Certified By Universal Robots

July 24, 2023

Verbotics Weld, our automatic robot programming software, has been certified by Universal Robots (UR)! We’re excited to become part of the UR+ ecosystem.

Read morePath Finding Using Force Sensing

June 8, 2023

Path finding is the key that allows an automatic offline program in Verbotics to be run in the real world without the need for touchup.

Read moreVerbotics Weld 0.11.2

June 1, 2023

We’ve just released a new version of our Verbotics Weld software with Doosan support and many other improvements. You can download the latest release here or by checking for updates within Weld.

Read moreFacility for Intelligent Fabrication Uses Verbotics To Accelerate Research and Training

May 21, 2023

The Facility for Intelligent Fabrication (FIF), located at the University of Wollongong in Australia, has recently announced a successful collaboration with Verbotics, a robotic automation software provider.

Read moreHow Does Programming Time in Verbotics Compare?

May 19, 2023

We often get asked how long it takes to program things with Verbotics Weld and how it compares to conventional programming.

Read moreWhat is the Robotics Cost Curve?

May 2, 2023

Have you heard about the Robotics Cost curve? It’s a concept that shows how robotic welding costs decrease with part volume.

Read moreVerbotics Sells 50 Licences of Its Software

April 13, 2023

Verbotics, a leading provider of cutting-edge automation and robotics software, recently announced that it has sold 50 licenses of its software to various businesses.

Read moreSupport for Doosan Cobots

March 2, 2023

We’re excited to announce that Verbotics Weld, our cutting-edge robotic welding software, now supports Doosan cobots! Doosan have a wide range of cobot models which are capable of working more closely with humans that traditional industrial robots.

Read moreVerbotics Weld 0.11.1

October 22, 2022

Today we’re excited to release Verbotics Weld 0.11.1! This minor release includes a number of improvements to existing features and bugfixes.

Read moreExperimentation with Surface Toolpaths

September 8, 2022

We have been working on a set of features for Verbotics Weld that will ease the offline programming for a whole class of processes that require toolpaths to be generated along the surface of a part.

Read moreTRT Case Study: Enabling High-Mix Low-Volume Production

August 2, 2022

Tidd Ross Todd Ltd (TRT) is a leading design and manufacturing company producing components for the road transport and construction industry. Founded in 1967, TRT prides itself on overcoming complex engineering challenges to “make things possible for our customers.”

Read moreVerbotics Weld 0.11

February 28, 2022

We’re pleased to release Verbotics Weld 0.11. The main features for this release are the ability to manually create or edit weld toolpath and calibration positions, 2D laser sensing, and support for KUKA and Universal Robots.

Read moreVerbotics Partners with UOW's Industry 4.0 Hub for Universal Robots Development

February 15, 2022

Verbotics partnered with the University of Wollongong’s Industry 4.0 Hub to add Universal Robots (UR) support. This will be included in the 0.

Read moreUsing Seam Tracking to Account for Part Variation

February 19, 2021

Did you know Verbotics Weld can be used to program the advanced welding functionality in your robot? Multi-pass welds, weaving, and through-arc seam tracking all can be programmed directly from the application.

Read moreVerbotics Weld 0.10 Released

February 16, 2021

We’re pleased to release Verbotics Weld 0.10. The main new feature for this release is multi-pass welding. We have improved how settings work to make managing large projects easier.

Read moreVerbotics Weld 0.9 Released

May 22, 2020

Today we have released Verbotics Weld 0.9 with improved visualisation, weld path editing and troubleshooting tools, improved calibration planning and many other improvements.

Read moreCase Study - Easy Programming for Bespoke Manufacturing

March 3, 2020

This steel fire pit was fabricated at the Facility for Intelligent Fabrication (FIF) in Wollongong using programs generated with Verbotics Weld.

Read moreLaser Sensing Support for Verbotics Weld

February 17, 2020

We have been working with Robotic Automation to add laser sensing capability to Verbotics Weld. Laser sensing uses a laser distance sensor to determine the position of the part, in a process similar to touch sensing.

Read moreVerbotics Developing FANUC Translator

February 10, 2020

We have partnered with Canmec to develop a FANUC TP translator for Verbotics Weld. This will enable Verbotics Weld to output robot code directly to FANUC robots.

Read moreVerbotics Weld 0.8 Released

February 4, 2020

Today we have released Verbotics Weld 0.8 with support for laser sensing, in-progress support for Fanuc robots and many other improvements.

Read moreVerbotics Weld 0.7 Released

August 5, 2019

We have released Verbotics Weld 0.7 which includes weld accessibility checking, locked positioner planning, additional axes support and a number of other enhancements.

Read more