This steel fire pit was fabricated at the Facility for Intelligent Fabrication (FIF) in Wollongong using programs generated with Verbotics Weld. It was a good example to demonstrate the capability for Verbotics Weld to enable bespoke robotic manufacturing.

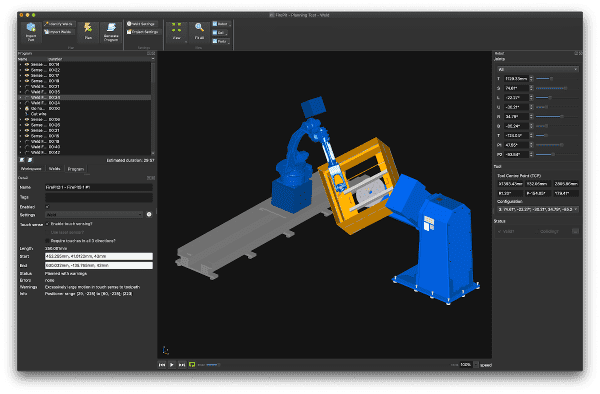

The fire pit consists of an inner and outer steel box structure made with 3mm mild steel. Each box was stitched welded together with 1.2mm wire. The welds were performed using a Yaskawa MA2010 on a 3 metre linear rail and a 2-axis “skyhook” workpiece positioner. The robot is equipped with a Lincoln Power Wave welding power source.

Verbotics Weld was used to create the welding programs for the robot. For this project no code modifications were required, all welds were performed using the automatic code generated directly from the software application. The output includes wire cutting and touch sense calibration. The stitch welds are also handled by Verbotics Weld by simply specifying the stitch length and gap

Click here for a simplified walkthrough of how this part was programmed →

In this project the positioner was free to move the workpiece during welding. While not necessary for this type of construction it was a good test for the planning algorithms within Verbotics Weld to show their capability to generate coordinated motions for the robot and workpiece positioner.

After automatically identifying the welds some time was spent in the project removing the welds that were not going to be welded. The next step was to create the weld settings, in this case the torch angles were left as the default settings, but the robot weld information, weave information, and stitch settings were added. Then Verbotics Weld was left to create the weld paths and motions. This took approximately 15 minutes of human interaction with the software, then 30 minutes for the computer to generate the paths for both parts.

The resulting weld quality was as expected from an advanced welding system. The calibration routines correctly compensated for any slight set up and positioning errors and each weld was consistent and of high quality.

This demonstrates how quickly you can go from a CAD drawing directly to a welding program with Verbotics Weld. Although this part was relatively simple, Verbotics Weld also works on more complex assemblies. If you would like to know more download a trial or get in contact with us.

About the Facility for Intelligent Fabrication

The Facility for Intelligent Fabrication (FIF) is a University of Wollongong, TAFE NSW and Weld Australia initiative to provide help and support for industries interested in implementing advanced manufacturing. This includes robotic welding automation facilities for demonstration and evaluation. Please visit the FIF website for more information.