Arronet Technik AB has been designing and manufacturing bespoke boats for over 30 years. Their boats are made entirely in-house with a distinctive unpainted aluminium design style. They produce around 200 boats annually ranging from 18-35 feet, with each boat customised for every order.

Download the case study Watch on YouTube

Client Issues

Arronet's journey into robotic welding began 15 years ago when they purchased a small robot. However, it wasn’t long before they began to run into some critical issues: programming for their high-mix production was difficult, and difficulty following the long curved weld seams.

Programming is very hard and following the seam was difficult. [...] Aluminium is a material that expands a lot during the long welds - then the robot misses the seam so we were restricted to small pieces.

While producing 200 boats there is a significant product variation. For example, in just their 23 foot length, there are 4 different models. There is a lot of variation in our production, this makes welding with the robot tricky.

Solution

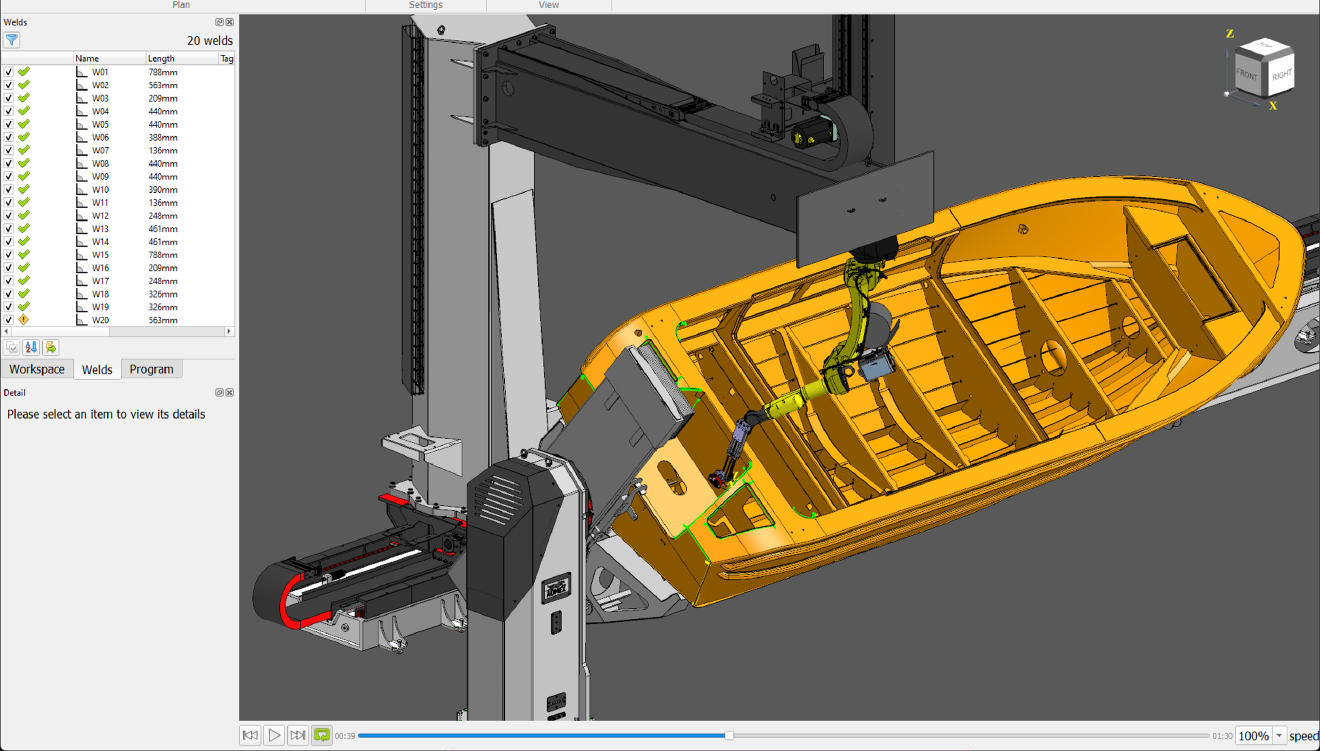

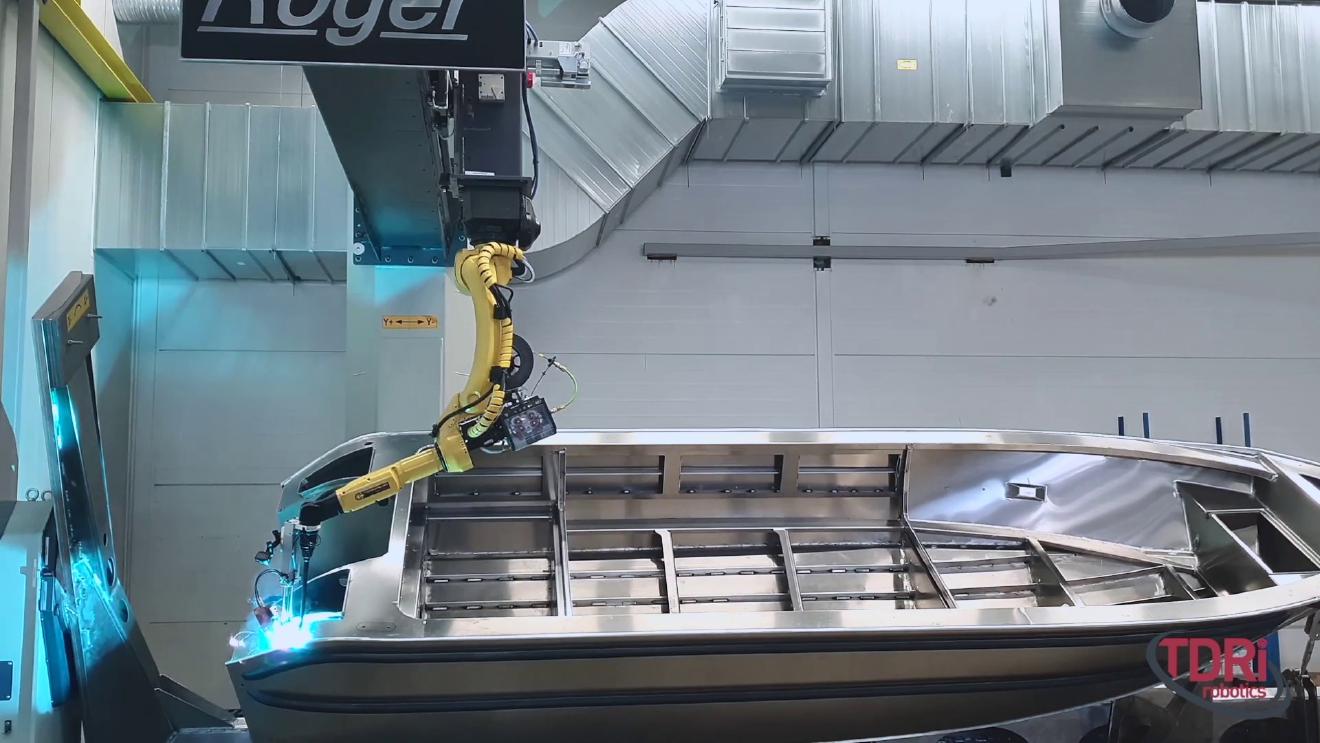

Arronet met with Gabor Szabo from TDRi Robotics who showed them that they could solve their main issues. Gabor brought a small robot with a laser tracking sensor to prove to Arronet that this technology would follow and track their curved seams. He also introduced Arronet to Verbotics Weld as the solution to their programming issues. Arronet were impressed with the solutions TDRi proposed and invested in a robotic gantry system capable of welding their largest boats.

Results

The robot system installed by TDRi and running the programs generated by Verbotics Weld is successfully welding complete boat hulls and is now a key part of their production process: It has been running for two years and welds all the small and middle sized boats in the robot cell - it’s very satisfying.

Johan Karlsson, Arronet’s Robot Welding Engineer is now able to generate a program for a big boat in just a matter of hours

, a task he would consider impossible without the help of Verbotics Weld.

Verbotics was quite easy. Basically, you tell Verbotics how you want to weld it and it helps you figure out the path - so it wasn't so complicated

Verbotics also eliminates downtime while producing programs for different models: If you start running it on the robot, you can start working on the next boat. You don’t need to stop production to work on the next model.

Future

Arronet is a forward thinking company. They are currently designing the Arrofoil, a foiling boat with impressive fuel efficiency. We reduced the fuel consumption to about a third of consumption in a traditional boat - It also flies above the waves and feels more like flying than boating.

This forward thinking extends to their production too. The partnership between Arronet, TDRi and Verbotics is now developing a solution to automate their deburring process. A robot with a 3D camera will automatically generate a path to deburr parts without any conventional programming.